A312 SS Pipes & Tubes, Plate, Sheet, Coil, Filler Wire, Coil

Precision Metal Industries is a leading manufacturer of high-quality stainless steel products, known for its advanced technology and commitment to excellence. Specializing in stainless steel solutions, Precision produces a wide range of products, including pipes, tubes, fittings, flanges, bars, plates, sheets, and coils. With a focus on durability, corrosion resistance, and precision engineering, our stainless steel products cater to diverse industries such as oil & gas, petrochemical, food & beverage, and construction. We ensures stringent quality control and adherence to international standards, providing reliable materials for demanding applications worldwide.

Stainless steel is a versatile and durable alloy primarily composed of iron, chromium, and other elements such as nickel and molybdenum. Its defining characteristic is its resistance to corrosion, which comes from the presence of at least 10.5% chromium. When exposed to air, chromium forms a thin, invisible oxide layer on the surface of the steel that protects it from rust and staining.

ASTM A403 stainless steel pipe fittings are offered in grades like 304, 304L, and 316 for high-pressure applications.

ASTM A182 stainless steel forged fittings are available in grades such as F304, F316, and F321, designed for high-strength applications.

ASTM A182 stainless steel flanges designed for robust applications requiring durability and corrosion resistance in piping systems.

ASTM A276 stainless steel round bars offering excellent strength and corrosion resistance for a wide range of industrial applications.

ASTM A312 stainless steel pipes and tubes are available in grades like TP304, TP304L, and TP316, designed for high-pressure applications

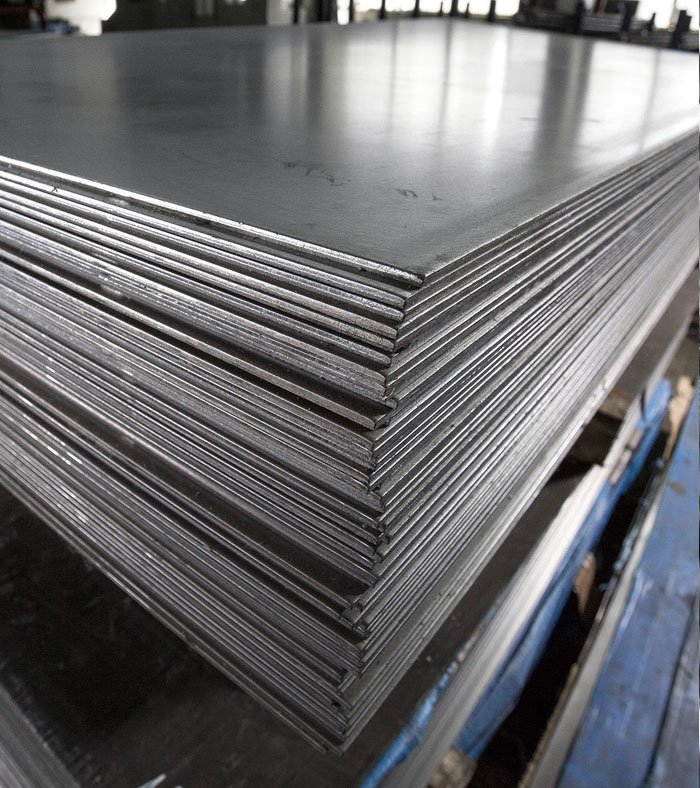

ASTM A240 SS plates, sheets, and coils are suitable for applications requiring strength & corrosion.

A182 stainless steel outlets are available in grades like F304, F316, and F321, designed for high-pressure applications and ensuring reliable connections.

ASTM A580 stainless steel filler wire is available in grades such as ER308, ER308L, and ER316L, specifically designed for welding applications.

ASTM A193/A194 stainless steel fasteners are offered in grades such as B8 (304), B8M (316), and B8T (321), providing high strength and corrosion resistance.

| Product | ASTM Standard | Common Grades |

|---|---|---|

| Pipe Fittings (Buttweld) | ASTM A403 | 304, 304L, 316, 316L, 321, 347, etc. |

| Forged Fittings | ASTM A182 | F304, F304L, F316, F316L, F321, F347, etc. |

| Flanges | ASTM A182 | F304, F304L, F316, F316L, F321, F347, etc. |

| Round Bar | ASTM A276, A479 | 304, 304L, 316, 316L, 321, 347, 410, 430 |

| Pipes & Tubes | ASTM A312, A213, A269 | TP304, TP304L, TP316, TP316L, TP321, TP347 |

| Plates, Sheets, Coils | ASTM A240, A666 | 304, 304L, 316, 316L, 321, 347, etc. |

| Outlets | ASTM A182 | F304, F304L, F316, F316L, F321, F347, etc. |

| Filler Wire | AWS A5.9, ASTM A580 | ER308, ER308L, ER316, ER316L, ER347 |

| Fasteners | ASTM A193, A194 | B8 (304), B8M (316), B8T (321), B8C (347) |

| Grade | UNS | ASTM | EN (DIN) | JIS | GOST | BS | AFNOR |

|---|---|---|---|---|---|---|---|

| 304 | S30400 | A240/A276 | 1.4301 (X5CrNi18-10) | SUS304 | 08Х18Н10 (08X18H10) | 304S15 | Z6CN18-09 |

| 304L | S30403 | A240/A276 | 1.4306 (X2CrNi18-9) | SUS304L | 03Х18Н11 (03X18H11) | 304S12 | Z2CN18-10 |

| 316 | S31600 | A240/A276 | 1.4401 (X5CrNiMo17-12-2) | SUS316 | 08Х17Н13М2 (08X17H13M2) | 316S31 | Z6CND17-11 |

| 316L | S31603 | A240/A276 | 1.4404 (X2CrNiMo17-12-2) | SUS316L | 03Х17Н14М3 (03X17H14M3) | 316S11 | Z2CND17-12 |

| 321 | S32100 | A240/A276 | 1.4541 (X6CrNiTi18-10) | SUS321 | 08Х18Н10Т (08X18H10T) | 321S31 | Z6CNT18-10 |

| 347 | S34700 | A240/A276 | 1.4550 (X6CrNiNb18-10) | SUS347 | 08Х18Н12Б (08X18H12B) | 347S31 | Z6CNNb18-10 |

| 310 | S31000 | A240/A276 | 1.4845 (X12CrNi25-20) | SUS310S | 20Х23Н18 (20X23H18) | 310S24 | Z12CN25-20 |

| 904L | N08904 | A240/A276 | 1.4539 (X1NiCrMoCu25-20-5) | SUS890L | - | - | Z2NCDU25-20 |

| 410 | S41000 | A240/A276 | 1.4006 (X12Cr13) | SUS410 | 12Х13 (12X13) | 410S21 | Z12C13 |

| 430 | S43000 | A240/A276 | 1.4016 (X6Cr17) | SUS430 | 12Х17 (12X17) | 430S17 | Z8C17 |

| Grade | C (%) | Cr (%) | Ni (%) | Mo (%) | Mn (%) | Si (%) | P (%) | S (%) | N (%) | Others |

|---|---|---|---|---|---|---|---|---|---|---|

| 304 | ≤ 0.08 | 18.0 - 20.0 | 8.0 - 10.5 | - | ≤ 2.00 | ≤ 0.75 | ≤ 0.045 | ≤ 0.03 | - | - |

| 304L | ≤ 0.03 | 18.0 - 20.0 | 8.0 - 12.0 | - | ≤ 2.00 | ≤ 0.75 | ≤ 0.045 | ≤ 0.03 | - | - |

| 316 | ≤ 0.08 | 16.0 - 18.0 | 10.0 - 14.0 | 2.0 - 3.0 | ≤ 2.00 | ≤ 0.75 | ≤ 0.045 | ≤ 0.03 | - | - |

| 316L | ≤ 0.03 | 16.0 - 18.0 | 10.0 - 14.0 | 2.0 - 3.0 | ≤ 2.00 | ≤ 0.75 | ≤ 0.045 | ≤ 0.03 | - | - |

| 321 | ≤ 0.08 | 17.0 - 19.0 | 9.0 - 12.0 | - | ≤ 2.00 | ≤ 0.75 | ≤ 0.045 | ≤ 0.03 | - | Ti: 5x(C+N) min. |

| 347 | ≤ 0.08 | 17.0 - 19.0 | 9.0 - 13.0 | - | ≤ 2.00 | ≤ 0.75 | ≤ 0.045 | ≤ 0.03 | - | Nb: 10x(C+N) min. |

| 310 | ≤ 0.25 | 24.0 - 26.0 | 19.0 - 22.0 | - | ≤ 2.00 | ≤ 1.50 | ≤ 0.045 | ≤ 0.03 | - | - |

| 410 | ≤ 0.15 | 11.5 - 13.5 | ≤ 0.75 | - | ≤ 1.00 | ≤ 1.00 | ≤ 0.04 | ≤ 0.03 | - | - |

| 430 | ≤ 0.12 | 16.0 - 18.0 | ≤ 0.75 | - | ≤ 1.00 | ≤ 1.00 | ≤ 0.04 | ≤ 0.03 | - | - |

| 904L | ≤ 0.02 | 19.0 - 23.0 | 23.0 - 28.0 | 4.0 - 5.0 | ≤ 2.00 | ≤ 1.00 | ≤ 0.045 | ≤ 0.035 | - | Cu: 1.0 - 2.0 |

| Grade | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) | Hardness (HB) | Hardness (HRB) | Hardness (HRC) |

|---|---|---|---|---|---|---|

| 304 | 515 - 750 | ≥ 205 | ≥ 40 | ≤ 201 | ≤ 92 | ≤ 22 |

| 304L | 485 - 700 | ≥ 170 | ≥ 40 | ≤ 183 | ≤ 88 | ≤ 20 |

| 316 | 515 - 750 | ≥ 205 | ≥ 40 | ≤ 217 | ≤ 95 | ≤ 22 |

| 316L | 485 - 700 | ≥ 170 | ≥ 40 | ≤ 217 | ≤ 95 | ≤ 22 |

| 321 | 515 - 750 | ≥ 205 | ≥ 40 | ≤ 217 | ≤ 95 | ≤ 22 |

| 347 | 515 - 750 | ≥ 205 | ≥ 40 | ≤ 217 | ≤ 95 | ≤ 22 |

| 310 | 515 - 730 | ≥ 205 | ≥ 40 | ≤ 217 | ≤ 95 | ≤ 22 |

| 410 | 415 - 735 | ≥ 205 | ≥ 20 | ≤ 217 | ≤ 95 | ≤ 22 |

| 430 | 450 - 750 | ≥ 275 | ≥ 22 | ≤ 183 | ≤ 88 | ≤ 20 |

| 904L | 490 - 690 | ≥ 220 | ≥ 35 | ≤ 192 | ≤ 90 | ≤ 20 |

© Copyright 2024. Developed By LHBM Infotech | Sitemap