Alloy Steel Plate, Sheet, Coil, Filler Wire, Coil, Pipes & Tubes Supplier

Precision Metal Industries (PMI) is a leading manufacturer and supplier of high-quality alloy steel products, catering to a diverse range of industries. With a commitment to excellence, We offers a wide selection of alloy steel materials, including pipe fittings, flanges, round bars, fasteners, and more. Our extensive inventory ensures that clients have access to various grades and specifications, tailored to meet the specific requirements of their applications. We focus on quality is reflected in their rigorous manufacturing processes and adherence to industry standards, providing customers with reliable and durable products. We dedicated to delivering exceptional customer service, ensuring timely deliveries and support throughout the purchasing process.

Alloy steel is a specialized form of steel that includes various alloying elements, such as chromium, nickel, molybdenum, and vanadium, in addition to carbon. These elements are introduced to enhance the steel's mechanical properties, including strength, toughness, hardness, and corrosion resistance. By adjusting the composition of these alloying elements, manufacturers can tailor alloy steel to meet specific performance requirements for a wide range of applications across various industries.

Commonly used in sectors such as automotive, aerospace, construction, oil and gas, and power generation, alloy steel is known for its versatility and durability. It can be classified into low-alloy and high-alloy steels, depending on the percentage of alloying elements present. This adaptability makes alloy steel ideal for applications that demand high performance, such as heavy machinery, structural components, and piping systems in extreme conditions.

Alloy Steel Pipe Fittings, such as ASTM A234 WPB and ASTM A420 WPL6, are designed to provide enhanced strength and corrosion resistance for high-pressure and high-temperature applications in various industrial sectors..

Alloy Steel Forged Fittings, including ASTM A105 and ASTM A182 F1, offer superior strength and durability for critical applications in high-pressure environments and are widely used in oil and gas.

Alloy Steel Flanges, such as ASTM A105 and ASTM A350 LF2, are engineered to provide reliable sealing and strength for high-pressure applications, making them essential components in various industries.

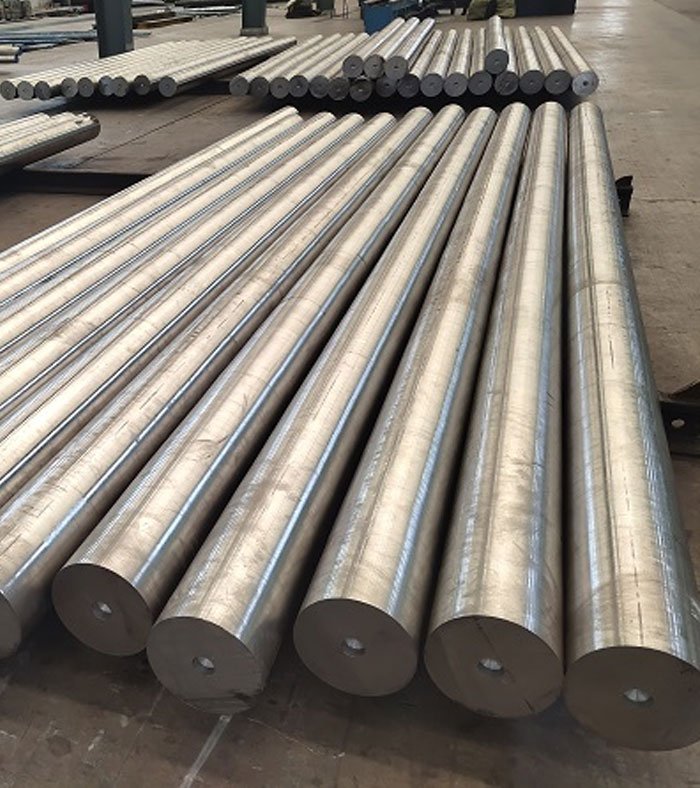

Alloy Steel Round Bars, including grades like ASTM A276 and ASTM A304, are known for their excellent mechanical properties and are commonly used in the manufacturing of shafts, gears, & other components.

Alloy Steel Pipe and Tube, such as ASTM A335 P5 and ASTM A213 T91, are designed for high-temperature and high-pressure applications, offering exceptional strength and resistance.

Alloy Steel Plate, Sheet, and Coil, including grades like ASTM A387 and ASTM A516, provide outstanding toughness and corrosion resistance, making them suitable for critical applications.

Alloy Steel Outlets, such as ASTM A234 WPB and ASTM A420 WPL6, are designed to provide reliable branching connections in piping systems, offering excellent strength and durability for high-pressure applications.

Alloy Steel Filler Wire, including grades like AWS A5.28 ER70S-6 and ER80S-D2, is specifically formulated for high-strength welding applications, providing excellent weldability and mechanical properties.

Alloy Steel Fasteners, such as ASTM A193 B7 and ASTM A320 L7, are engineered to deliver superior strength and corrosion resistance, making them ideal for high-stress applications in demanding environments.

| Product | ASTM Grade |

|---|---|

| Pipe Fittings | A234 WP5, A234 WP9, A234 WP22 |

| Flange | A182 F5, A182 F9, A182 F22 |

| Round Bar | A479 S31803, A479 S32750 |

| Fasteners | A193 B7, A193 B16 |

| Pipes & Tubes | A335 P5, A335 P9, A335 P22 |

| Plate, Sheet, Coil | A387 Gr 5, A387 Gr 9, A387 Gr 22 |

| Filler Wire | A5.28 ER80S-B2, A5.34 ER70S-6 |

| Outlet | A234 WP5, A234 WP9 |

| Forged Fittings | A105, A182 F5, A182 F9 |

| Grade | ASTM | EN (DIN) | JIS | GOST | BS | AFNOR |

|---|---|---|---|---|---|---|

| 4130 | A519 | 1.7220 (30CrMo) | SCM430 | 40Х (40H) | 4130S | Z6C3S |

| 4140 | A519 | 1.7225 (42CrMo4) | SCM440 | 40ХН (40HN) | 4140S | Z6C4S |

| 4340 | A508 | 1.6564 (34CrNiMo6) | SCM440 | 45Х2М (45X2M) | 4340S | Z6C4S |

| 8620 | A574 | 1.6523 (20CrMo) | SCM620 | 20Х (20H) | 8620S | Z6C3S |

| 9310 | A829 | 1.5961 (10NiCrMo9) | SCM910 | 25Х2Н (25X2H) | 9310S | Z6C3S |

| Grade | C | Mn | P | S | Cr | Mo | Ni | Si | Fe |

|---|---|---|---|---|---|---|---|---|---|

| 4130 | 0.28-0.33 | 0.60-0.90 | ≤0.035 | ≤0.040 | 0.40-0.60 | 0.15-0.25 | 0.10-0.40 | 0.15-0.40 | Balance |

| 4140 | 0.38-0.43 | 0.75-1.00 | ≤0.035 | ≤0.040 | 0.80-1.10 | 0.15-0.25 | 0.15-0.40 | 0.15-0.40 | Balance |

| 4340 | 0.38-0.43 | 0.60-0.80 | ≤0.035 | ≤0.040 | 0.70-0.90 | 0.15-0.25 | 1.50-2.00 | 0.15-0.40 | Balance |

| 8620 | 0.18-0.23 | 0.60-0.90 | ≤0.035 | ≤0.040 | 0.30-0.60 | 0.15-0.25 | 0.70-1.00 | 0.15-0.40 | Balance |

| 9310 | 0.18-0.23 | 0.40-0.60 | ≤0.035 | ≤0.040 | 0.40-0.60 | 0.20-0.30 | 1.40-1.80 | 0.15-0.40 | Balance |

| Grade | Yield Strength (MPa) | Tensile Strength (MPa) | Elongation (%) | Hardness (HB) | Impact Energy (J) |

|---|---|---|---|---|---|

| 4130 | 310-450 | 560-750 | 20-25 | 197-262 | 27 (at -20°C) |

| 4140 | 415-620 | 655-850 | 15-20 | 217-285 | 27 (at -20°C) |

| 4340 | 460-780 | 760-980 | 12-18 | 235-302 | 35 (at -20°C) |

| 8620 | 345-500 | 570-750 | 20-25 | 197-270 | 35 (at -20°C) |

| 9310 | 450-690 | 690-910 | 12-18 | 225-302 | 45 (at -20°C) |

© Copyright 2024. Developed By LHBM Infotech | Sitemap